In the world of industrial vehicles, the effectiveness and reliability of the braking system are paramount. As technology advances, so does the complexity of these systems, making it essential for fleet operators and vehicle manufacturers to understand the best practices in selecting a high-performance braking system. This article delves into the critical components of braking systems, factors influencing their performance, and provides insights on how to choose the most effective system according to specific industrial needs.

The Core Components of an Industrial Braking System

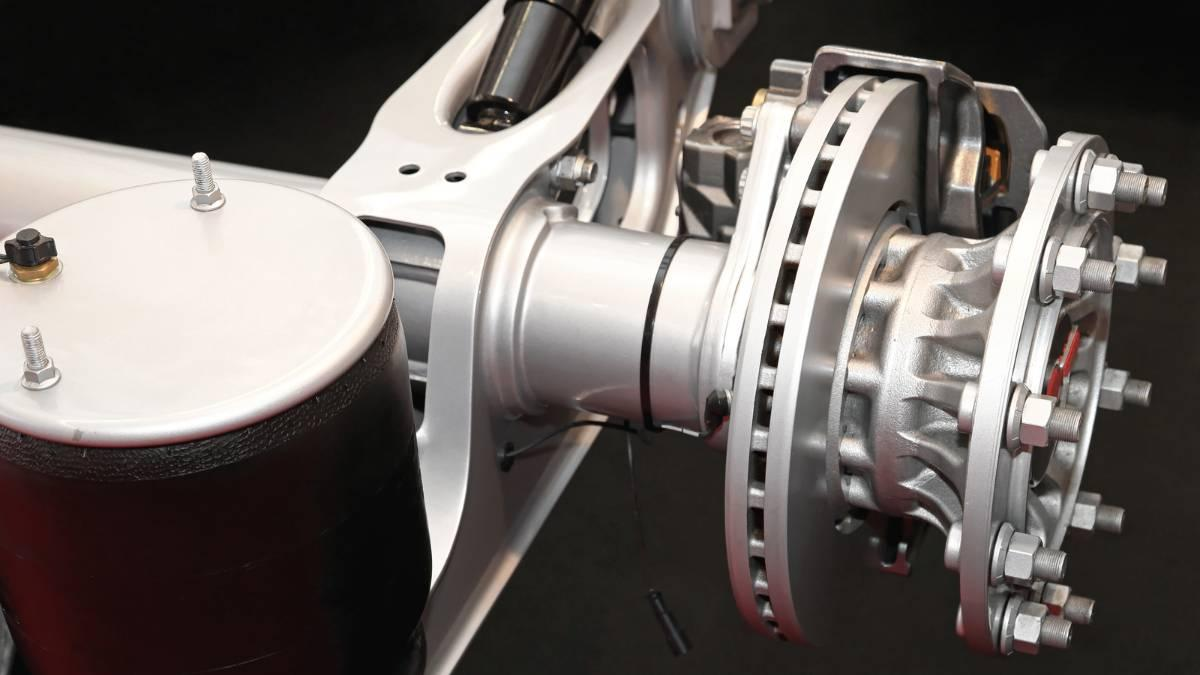

Understanding the core components that make up an industrial vehicle’s braking system is crucial for anyone involved in the maintenance or design of these heavy-duty machines. At the heart of this system are the brake pads, rotors, calipers, and the braking fluid network, which work together to halt the motion efficiently. Each component has its unique role, yet they must all function in unison to ensure safety and performance. Discussing Haldex parts, renowned for their quality and durability, can offer deeper insight into excellent manufacturing standards in modern braking technology.

Brake Pads and Rotors

Brake pads and rotors are directly impacted during the braking process. The materials used in these parts vary widely, from metallic compounds to organic formulations, each offering different benefits concerning durability and heat resistance. For instance, metal brake pads can handle extreme conditions but may wear down the rotor faster than ceramic pads. Selecting the right material based on the vehicle’s usage can significantly enhance the lifespan and functionality of the braking system.

Hydraulic Systems versus Air Brake Systems

In the realm of industrial vehicles, hydraulic and air brake systems represent two predominant technologies. Hydraulic brakes, commonly found in smaller vehicles, utilize a fluid-filled system to transfer force from the pedal to the brakes. On the other hand, larger, heavier vehicles usually feature air brakes, which use compressed air for significant stopping power without the risk of fluid leakage. Each type has its specific maintenance requirements and functional advantages under varying operational conditions.

Factors Influencing Braking Performance

Several intrinsic and extrinsic factors play critical roles in defining the efficacy of a braking system. Understanding these can help in optimizing the system for specific industrial applications.

Vehicle Weight and Load Dynamics

The total weight and distribution of cargo are pivotal in determining the appropriate braking system. Heavy-duty trucks carrying variable loads require robust, adaptable brake systems that can provide consistent performance regardless of changes in load weight. Incorrectly calibrated brakes can lead either to decreased efficiency or increased safety risks.

Environmental Conditions

Environmental conditions such as temperature, terrain, and weather also considerably affect brake performance. For example, operating in cold climates necessitates brakes that can perform reliably despite low temperatures and potential ice formation, whereas mountainous terrain requires brakes with higher endurance against prolonged descents. Fleet operators must consider these factors when choosing brake systems to ensure optimal adaptability and safety.

Braking System Technologies & Innovations

The evolution of braking technologies continues to transform the landscape of industrial vehicle performance. Innovations such as anti-lock braking systems (ABS), electronic brakeforce distribution (EBD), and regenerative braking contribute not only to enhanced safety but also to the sustainability of vehicles by improving fuel efficiency and reducing wear and tear.

Anti-lock Braking Systems (ABS)

ABS prevents wheel lock-up during sudden stops or slippery conditions, ensuring that the wheels continue to rotate and maintain traction with the ground. This technology dramatically improves steering control during emergency braking situations, thereby enhancing overall vehicle safety.

Electronic Brakeforce Distribution (EBD) and Regenerative Braking

EBD automatically varies the amount of force applied to each wheel, optimizing the braking performance based on current load distribution and driving conditions. In contrast, regenerative braking technology, primarily utilized in electric and hybrid vehicles, recaptures energy typically lost during braking and redirects it to recharge the battery. These advancements not only improve braking efficacy but also promote better fuel economy and reduced environmental impact.

- Ensuring routine checks and maintenance.

- Upgrading to higher-quality brake components as needed.

- Training staff on proper vehicle handling techniques.

The selection of a high-performance braking system for industrial vehicles is a nuanced decision that requires a comprehensive understanding of various factors and components. By integrating advanced technologies and conducting regular maintenance, fleet operators can vastly improve the safety and efficiency of their vehicles.